- First project: Collision Detection System

- Main components

- Brake system operation

- Technical advantages

- Second Project: Aerial Platform Control System

- System Architecture

- Main Components

- HMI Interface

- Safety Functions Guaranteed by Regulation

- Regulatory Compliance

- Technical Advantages

- Third Project: Custom Radio Kit

- System Architecture

- Regulatory Compliance

- Technical Advantages

- Diaboard

ALMEC and the Indian market: tailored innovation for local manufacturers

ALMEC strengthens its presence in India by providing automation solutions tailored to local sectors.

India today represents a rapidly expanding market, strategic for automation solutions and custom electronic systems. ALMEC provides concrete support to local manufacturers by developing tailor-made projects in direct collaboration with clients.

Thanks to the know-how gained in industrial automation and electronics applied to off-highway vehicles, in 2025 our team launched three major collaborations with leading companies in India, bringing innovation and reliability to key sectors of the national economy:

Agriculture: integration of ADAS systems on agricultural machinery, developed together with an Indian manufacturer, aimed at increasing safety in field operations and preventing accidents through advanced electronic solutions.

Aerial platforms: renewal of the hydraulic lifting system for an aerial platform, introducing an electronic control system capable of managing boom movements and automatic leveling of the structure, in compliance with technical and safety standards.

Construction: design and development of a fully customized radio-controlled system for the automation of construction machinery.

These projects confirm ALMEC’s ability to transfer and apply its expertise across diverse fields, delivering customized solutions aligned with the specific needs of each client.

First project: Collision Detection System

The Collision Detection System is designed to enhance the operational safety of industrial and off-highway vehicles, significantly reducing the risk of collisions both during driving and maneuvering. The system draws inspiration from ADAS technologies already widespread in passenger cars, adapting them to the requirements and operating conditions of agricultural vehicles.

Thanks to native integration with the vehicle’s CANBUS network, the system constantly monitors speed, driving direction, and the presence of obstacles along the trajectory, intervening in real time with visual and acoustic alerts and, when necessary, with automatic brake activation. Its effectiveness is particularly high during low-speed maneuvers, up to about 25 km/h, where collision risk reduction is most significant and intervention margins are adequate.

Thanks to native integration with the vehicle’s CANBUS network, the system constantly monitors speed, driving direction, and the presence of obstacles along the trajectory, intervening in real time with visual and acoustic alerts and, when necessary, with automatic brake activation. Its effectiveness is particularly high during low-speed maneuvers, up to about 25 km/h, where collision risk reduction is most significant and intervention margins are adequate.

Main components

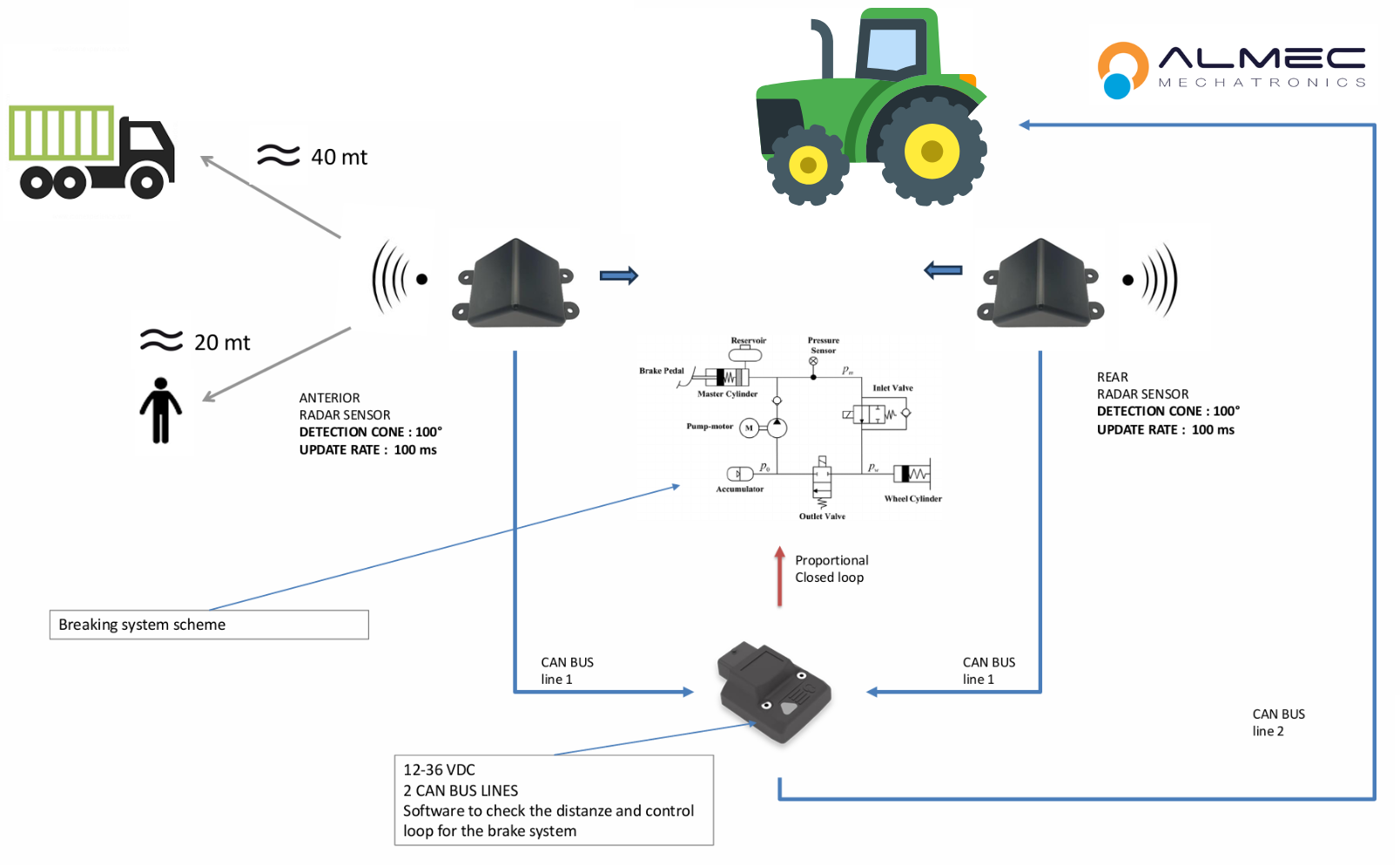

Front radar: detects obstacles in front of the vehicle and calculates distance and speed up to 40 m with a 100° cone.

Rear radar: assists during reversing maneuvers, preventing collisions up to 20 m with a 100° cone.

ADAS (Master ECU): processes radar data in real time, generates collision alerts, and automatically activates braking when required.

Brake system operation

The control software uses a proportional closed-loop command that analyzes the distance from obstacles, calculates the required deceleration, and activates the brake progressively to ensure stability and avoid sudden lock-ups.

Technical advantages

Scalability: easily integrable on any vehicle via CAN bus.

Active safety: combines driver alerts with automatic braking.

Reliability: redundant and robust architecture ensuring continuous operation.

Second Project: Aerial Platform Control System

The automation kit has been developed for an aerial platform intended for both the Indian market and beyond. The system enables complete management of movements, stability, and load control, integrating all safety functions required by the EN280-1:2022 standard for Mobile Elevating Work Platforms (MEWP).

System Architecture

System Architecture

The CANBUS network is the communication infrastructure that connects the various system components and operates with the CANOpen protocol, organized in a master-slave structure:

Master: a main unit manages and processes the machine’s program. The reference ECU is the SPN6, located in the control panel at the base of the vehicle, responsible for machine commands and diagnostics.

Slave: the secondary unit of the system – the Basket Control Panel, installed on the operator’s basket, performs this function by allowing the operator to interact with the machine and operate it in compliance with regulations. The slave units also host sensors such as the TRS.184, which support vehicle automation and ensure diagnostics and operational reliability. The entire design uses a reduced cable bundle to guarantee greater efficiency and ease of integration.

Completing the architecture is the CAN Gateway, a modem that enables interconnection and remote diagnostics: through the dedicated portal, the system status can be monitored and any anomalies detected even from a distance.

Main Components

Redundant bi-axial CAN-BUS tilt sensor – TRS.184: measures vehicle inclination on two axes. Redundancy ensures more accurate and reliable data, guaranteeing the safety required by the highest standards.

CAN-BUS load cell: detects weight or applied force up to 1 ton, useful for monitoring loads and stability.

Magnetic multi-turn CAN-BUS encoder: measures angular position precisely; equipped with memory to provide the absolute angle value even after shutdown.

Wire transducer with integrated inclinometer: combines linear displacement measurement (via wire) with inclination measurement, useful for monitoring boom extension movements.

Pressure transducer: measures hydraulic system pressure, essential for monitoring circuits and ensuring operational safety.

Axial suspension sensor: monitors axle position to verify correct vehicle placement on stabilizers.

Stabilizer limit switches: indicate when stabilizers are fully extended or retracted, ensuring safe operations.

HMI Interface

The HMI interface, integrated into the basement control panel, is the operator’s main access point. The system offers several functions organized into intuitive pages. The home page displays real-time machine status and operating conditions; the stabilizer menu allows extension control and safety parameter verification; the alarm page highlights errors or lock conditions for immediate intervention; the statistics section collects usage and performance data for monitoring and analysis; and advanced settings enable calibration and system configuration according to operational needs.

Safety Functions Guaranteed by Regulation

As required by regulations, the system automatically stops movement in case of anomalies. For example: overload is detected by the load cell; machine and platform/basket inclination is monitored by redundant tilt sensors; and emergency situations are managed by dedicated push buttons on the control panels.

Regulatory Compliance

The kit complies with major European directives:

EN280-1:2022 – Mobile Elevating Work Platforms (MEWP): This European standard defines stability, safety, and testing requirements for MEWPs, establishing precise rules that guarantee machine reliability. It requires platforms to maintain stability under load and inclination, mandates protection systems against risks of falling, overturning, or misuse, and requires each model to pass standardized tests before being placed on the market.

Electrical safety – SELV/PELV criteria: SELV (Safety Extra Low Voltage) and PELV (Protective Extra Low Voltage) are design criteria that mandate the use of very low and safe voltages.

Technical Advantages

Redundancy: tilt sensors and load cells with dual channel.

Remote diagnostics: CAN gateway for web-based monitoring.

Reliability: waterproof wiring and certified components.

Active safety: automatic management of overload, tilt, and emergency.

Third Project: Custom Radio Kit

The project involves replacing the AL50R radio control with the new NEXWAVE remote control. This is a bidirectional remote control system, developed for industrial lifting machines, material handling equipment, and aerial platforms, featuring secure and coded radio communication.

System Architecture

System Architecture

NEXWAVE waist-mounted remote control → remote command device with a fully customized manipulator layout, equipped with the RDC EVO receiver, replaceable battery with up to 24h autonomy, customizable interface, ultra‑resistant materials, Hamming coding for interference protection, 100m operating range, and optional wired CAN‑BUS connection.

Charging → performed via a dedicated charger with USB Type‑C connector; an LED display indicates charging status and any errors.

The device is fully customized for the client and produced in a limited series, designed for specific applications and small production volumes.

Regulatory Compliance

The system is designed according to the main European directives:

Electromagnetic Compatibility (EMC): the system does not interfere with other devices and resists external disturbances.

Radio Equipment Directive (RED): wireless communications operate correctly and without interference.

Technical Advantages

Reliability: proprietary radio protocol with Hamming coding to reduce transmission errors.

Autonomy: removable battery with internal CPU for monitoring cycles, temperature, and authenticity.

Robustness: IP65 housing, operational in extreme environmental conditions.

Ergonomics: console with shoulder strap, customized printed keyboard, and intuitive interface.

Scalability: compatible with existing systems through retrofit.

Diaboard

The three projects described can be connected with Diaboard, ALMEC’s digital platform that makes industrial machinery intelligent and interconnected.

Diaboard brings efficiency and safety to the core of construction and industrial mobility, transforming every machine into a digital asset capable of “speaking” with the operator and with the entire jobsite ecosystem.

It integrates real-time monitoring and geolocation with advanced geofencing functions, offering a modular and scalable architecture suitable for different sectors; it reduces downtime and optimizes maintenance.

Fleet management, OTA updates, reporting, and interoperability with ERP systems ensure efficiency and complete integration. Diaboard delivers safety, reliability, and competitiveness at the heart of industrial mobility.

For more information or to request a consultation with a technician, contact us at info@almec.net.